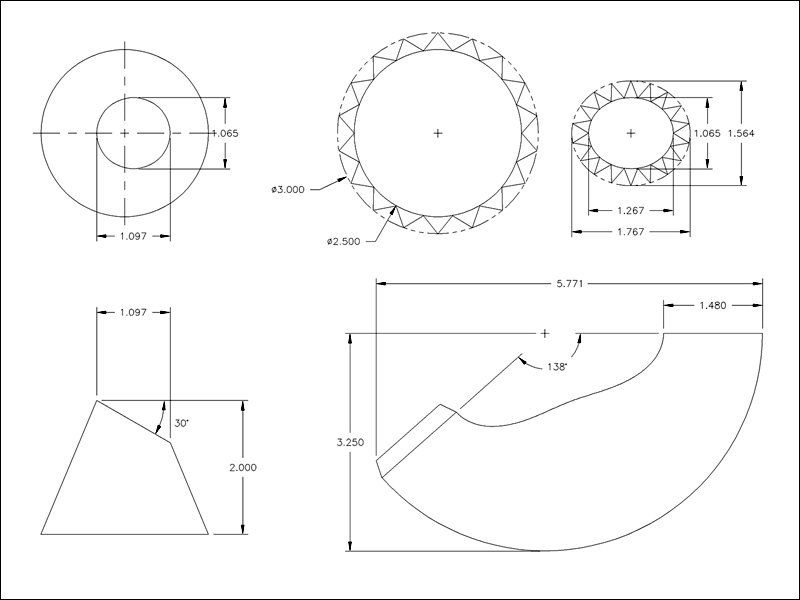

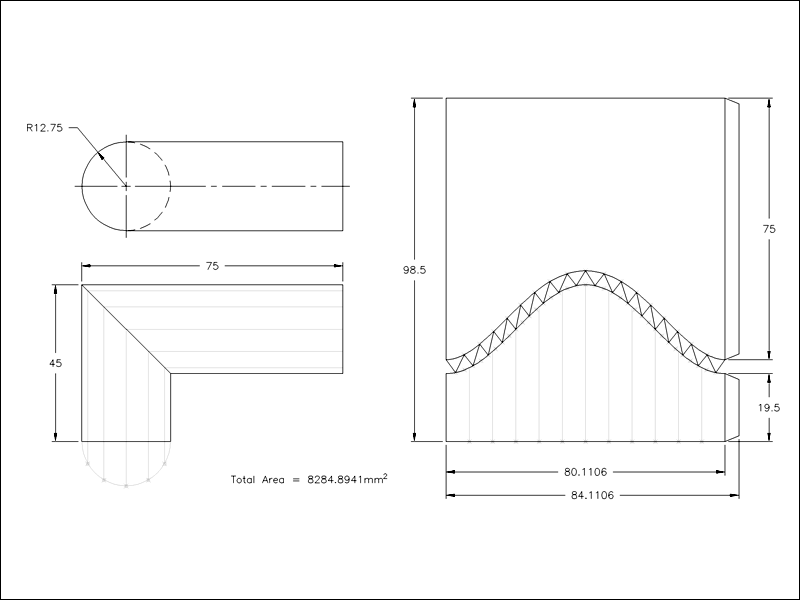

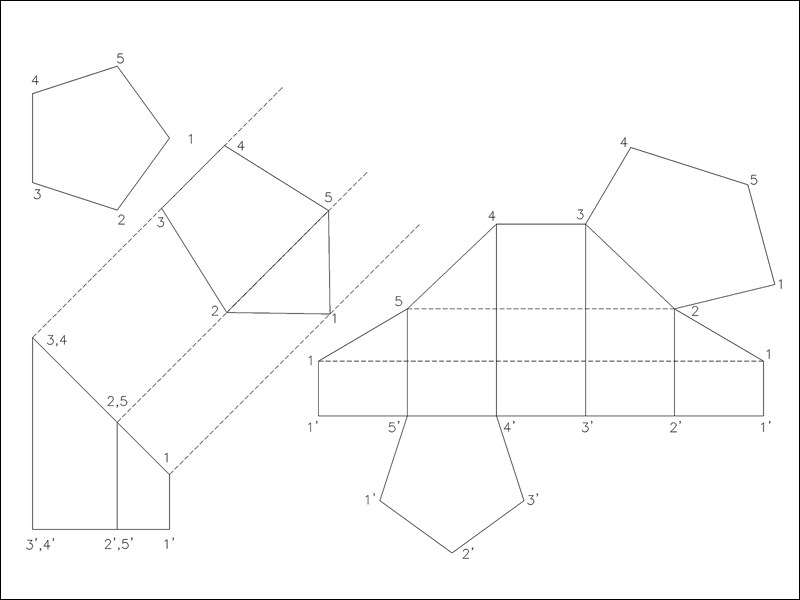

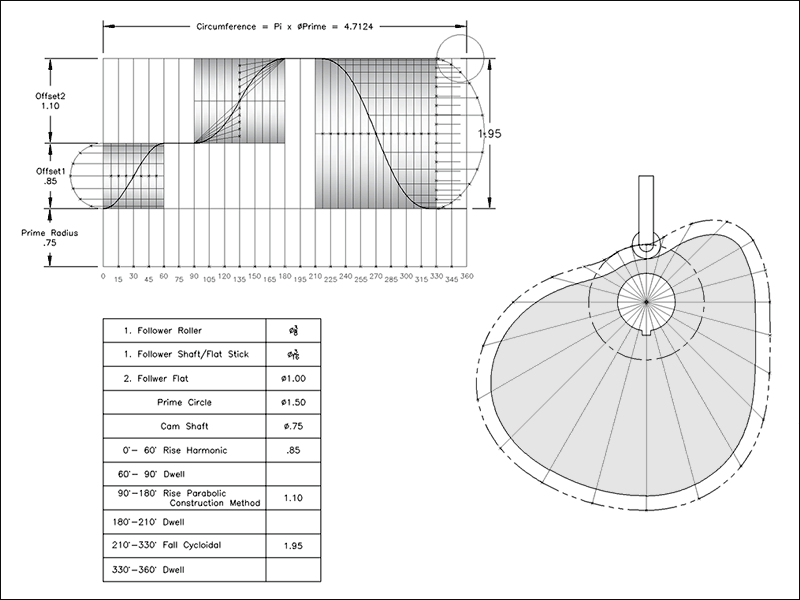

M16 – Pyramids, Cones & Funnels

Module 16 - Producing Development Drawings: Produce development (construct) drawings of different object shapes. Draw the intersection of sheet metal parts (T/Y duct and pipe connections). Compute the required material quantity and sheet layout. Determine bend allowance in bent and formed parts. ...

Continue Reading